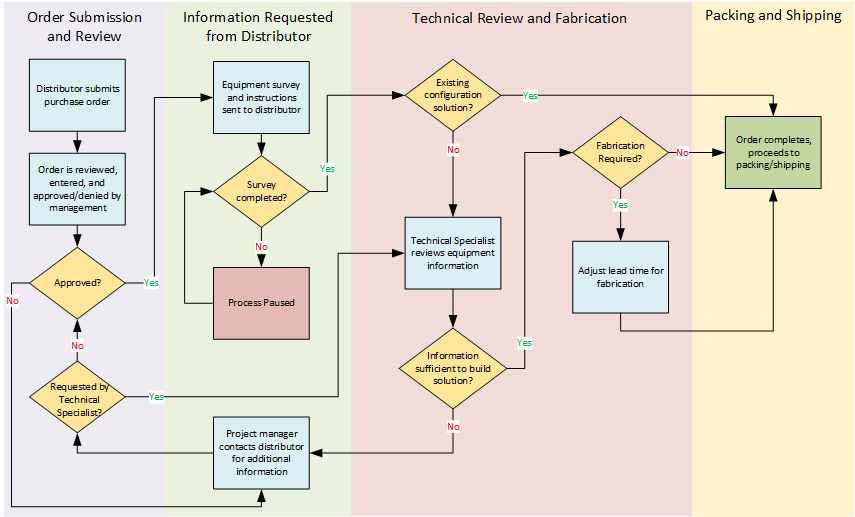

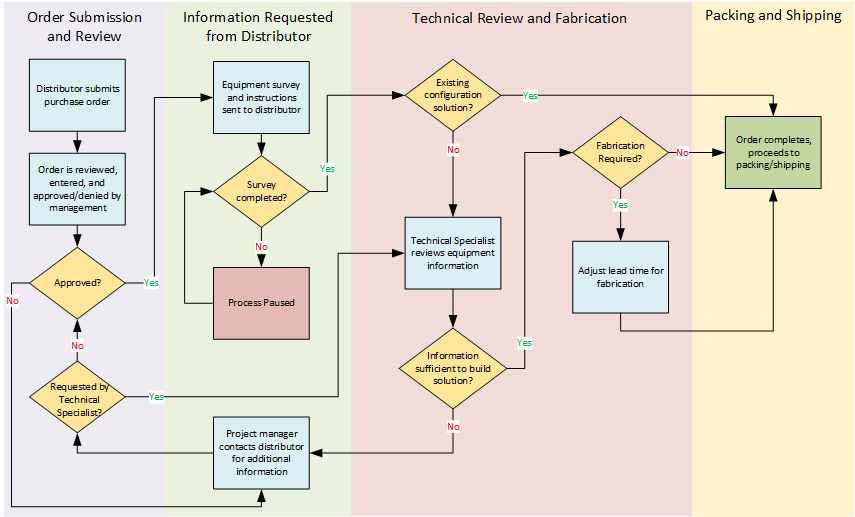

System Order Process

The system order process as diagrammed above consists of a steps that must proceed sequentially in order for Card Concepts to provide a high level of service to our distributors and operators. These steps are further outlined in sequence below:

- Distributor contact submits a purchase order through email or fax to a member of the sales team or Orders@LaundryCard.com.

- Purchase order is reviewed and submitted to the appropriate project manager.

- Purchase order is reviewed by the processor and entered into in-house order processing software.

- Completed in-house order and purchase order are reviewed by management for error-checking and approved or denied as appropriate.

- Denial results in seeking further information from the distributor contact.

- Approved orders proceed to step 5.

- Once a purchase order is approved by management, a confirmation email is sent to all distributor contacts listed on original purchase order. This email contains the approved purchase order as an attachment. The email body contains instructions that must be completed before step 6 may begin. It also contains an estimated lead-time.

- Lead time is contingent upon the emailed instructions being completed and does not begin until equipment survey is submitted by distributor.

- Equipment survey must be completed by a distributor contact familiar with the equipment on which CCI hardware is intended to be mounted.

- Order process holds until step 5 is completed and equipment survey is received.

- Received equipment survey is analyzed by project manager to identify that all requisite equipment details have been provided.

- If information is incomplete, project manager will contact listed distributor contact for clarification.

- Machine models and other requested information are compared against our database to check for existing hardware configuration solutions.

- If an existing hardware configuration solution exists, the order process can proceed step 10.

- If no existing hardware configuration solution exists, the order process pauses and proceeds to step 9.

- In the event that an order is submitted that requires interfacing with hardware for which we have no standard existing solution, the details of the order are submitted to a technical specialist who performs the following:

- Specialist reviews the order details regarding the equipment in question.

- Specialist analyzes available technical information provided by the equipment manufacturer and may reach out to manufacturer for clarification.

- Specialist may request that distributor submit pictures of certain equipment components to determine necessary harnessing, mounting considerations, etc.

- These requests are typically submitted to the distributor through the project manager to the listed distributor contact provided on the equipment survey.

- Specialist research is often contingent upon information being provided by manufacturer or distributor contacts and is therefore subject to delay. This may affect lead time.

- Specialist finalizes and recommends viable hardware configuration solution based upon research and details provided.

- If the hardware configuration utilizes new components that require fabrication, this will affect lead time.

- Specialist updates installation guides for new solution.

- Specialist submits results to project manager.

- Project manager completes order.

- Order proceeds to packing and shipping.